Undersea Pipeline Inspection

Advanced Pressurized Pipeline Inspection & Leak Detection Long Range

High-Precision Solutions for Large-Diameter Water Mains

When critical water mains cannot be taken out of service, traditional inspection methods often fall short. Our long-range, tethered inspection technology is designed specifically for pressurised, large-diameter pipelines, delivering accurate condition assessment with no service disruption.

We help utilities and operators eliminate uncertainty, reduce risk and locate hidden issues—quickly and cost-effectively.

Why Choose Our Technology?

Engineered for Complex Environments

Our systems operate in pipelines that are:

- Deeply buried

- High pressure

- Long-distance with multiple bends

- Large diameter and low accessibility

These conditions make many standard inspection techniques unreliable or unsafe. Our specialised method is purpose-built for environments where other solutions cannot be used.

Long-Range Tethered Inspection System

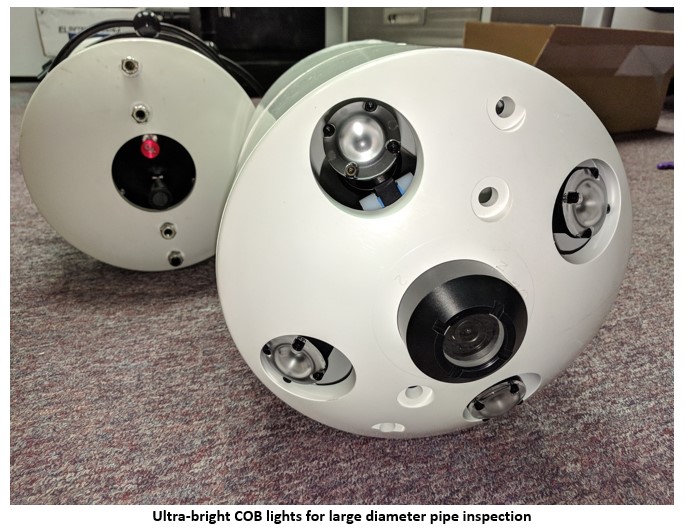

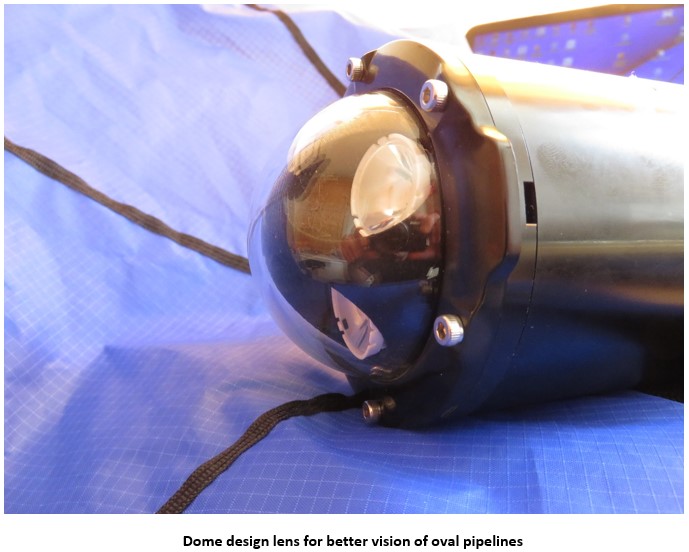

Our pressure-rated camera and acoustic sensor module is connected to a multi-kilometre tether, allowing operators to inspect extended pipe sections under live flow. The system enters the pipe through small access points and can travel long distances in a single deployment.

Real-time Data Includes:

- High-resolution internal video

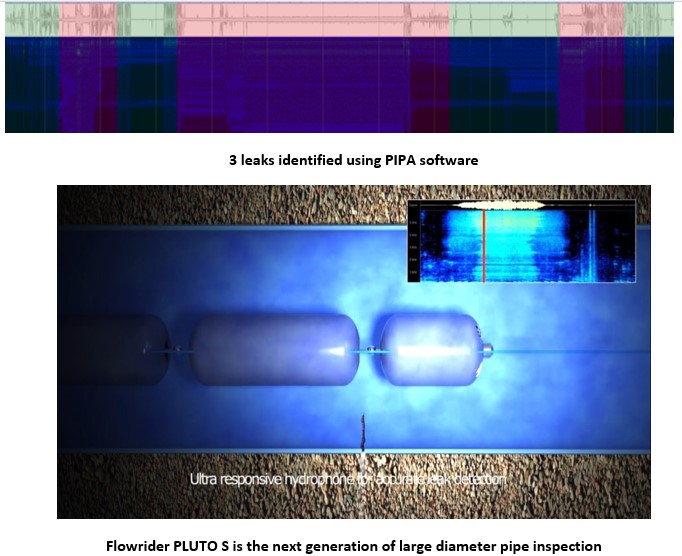

- Leak detection via sensitive acoustic monitoring

- Temperature and pressure readings

- Identification of blockages, air pockets, bends and joints

All measurements are logged with precise distance tracking for accurate reporting.

How the Inspection Works

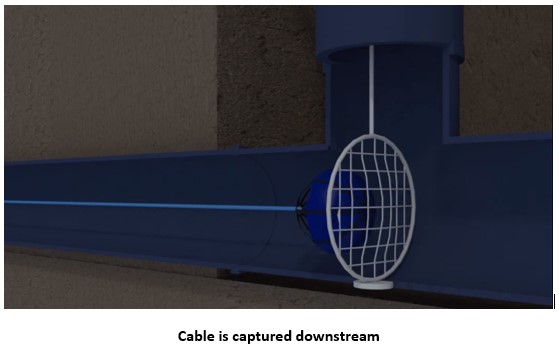

- Insertion Under Pressure

A launch unit introduces a flow-driven carrier and tether into the main without interrupting service. - Controlled Capture Downstream

A retrieval assembly safely collects the carrier while the line remains live and pressurised. - Full Internal Survey

The inspection head is pulled back through the pipeline, capturing continuous visual and acoustic data. - Comprehensive Reporting

All results are analysed and delivered in a structured report detailing defects, anomalies and areas of interest.

What Clients Gain

- Accurate condition assessment of large water mains

- Early detection of leaks—from minor seepage to major failures

- Confirmation of internal integrity without excavation

- Reduced operational risk and cost

- Fast project turnaround—typically within a single shift

Our technology removes guesswork, allowing operators to make informed decisions with confidence.

A Smarter Way to Inspect Critical Infrastructure

For utilities seeking a dependable, non-disruptive method to evaluate essential water assets, our long-range inspection solution delivers unmatched clarity and reliability. Whether the goal is leak detection, blockage identification or structural assessment, our system provides the insight you need—when you need it.