Video and Acoustic Inspection of Pressurized Waterlines

Video & Acoustic Inspection of Pressurized waterlines

Inspecting drinking water pipelines has traditionally required shutdowns, service disruption, or limited visibility. Today, advanced inspection technology makes it possible to assess pressurized waterlines from the inside—safely, accurately, and without interrupting supply.

XPIPE offers video and acoustic inspection solutions for pressurized pipelines, providing critical insights into pipe condition, leaks, and internal structures while the system remains fully operational.

Advanced Inspection Technology for Pressurized Pipelines

This inspection method is based on proven, long-term technology developed specifically for water networks under pressure. It has been refined through years of operational use and is now recognized as a reliable, non-invasive alternative to traditional inspection methods.

The technology enables utilities and infrastructure owners to:

Inspect pipelines without depressurizing

Preserve water quality and service continuity

Access high-quality visual and acoustic data in real time

Proven Performance on Diverse Water Networks

The inspection systems are suitable for:

A wide range of pipe diameters

Multiple pipe materials (metallic and non-metallic)

Old and modern water infrastructure

Even aging pipelines can be safely inspected, delivering valuable condition data without increasing risk.

Inspection Systems Overview

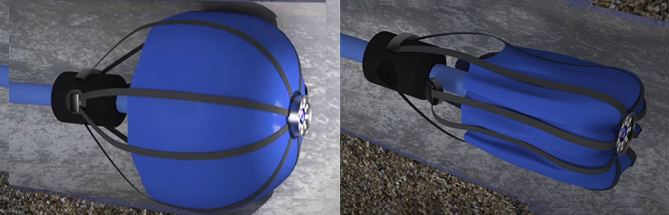

Hydrocam™ – Video & Acoustic Inspection

Hydrocam™ combines high-resolution visual inspection with acoustic leak detection, allowing operators to:

Identify leaks using sensitive hydrophones

Visually confirm pipe condition

Locate valves, joints, defects, and anomalies

Track camera position with integrated cable detection

This dual-function approach significantly improves diagnostic accuracy.

Flowrider™ Lite – Long-Distance Inspection

Flowrider™ Lite uses the natural flow of water to transport the inspection unit through the pipeline:

Inspection distances up to 1,000 meters

Ideal for long, straight pipeline sections

Fully approved for use in drinking water systems

All equipment remains securely tethered, ensuring complete control and zero risk of loss inside the pipeline.

What This Technology Enables

Video and acoustic inspection of pressurized waterlines provides actionable intelligence, including:

Condition assessment of pipelines under pressure

Precise leak and blockage localization

Detection of undocumented connections

Identification of pipe materials and internal linings

Early recognition of causes of water discoloration or quality issues

This allows infrastructure owners to intervene earlier, target maintenance more precisely, and reduce long-term costs.

A Strategic Tool for Water Infrastructure Management

The inspection data supports:

Asset management and lifecycle planning

Preventive maintenance strategies

Risk mitigation and emergency prevention

Better-informed investment decisions

By understanding actual pipe conditions, organizations can move from reactive repairs to data-driven infrastructure management.

Scalable, Flexible & Future-Ready

The technology is designed to:

Adapt to different network sizes and configurations

Scale from short inspections to long-distance surveys

Integrate into existing maintenance workflows

Its flexibility makes it equally suitable for public utilities, private operators, and specialized inspection contractors.

Why Choose XPIPE

No shutdowns or service interruptions

Approved for drinking water systems

Combined visual and acoustic inspection

Suitable for aging and modern pipelines

Faster inspections with higher-value data

Need full visibility inside your pressurized water network—without disrupting operations?

Contact Xpipe to learn how video and acoustic inspection technology can transform the way you manage critical water infrastructure.